Advertisment

DrugLog – rapid quality control for compounded injections

DrugLog is a bench-top device that allows rapid verification of the identity and concentration of a drug in a prepared injection. Originally conceived for quality control of compounded, patient-specific injections, this versatile device is now finding wider applications. IMI spoke to Mats Högberg, CEO of Pharmacolog AB, the Swedish company that makes DrugLog to find out more.

Pharmacolog AB was founded in about 2007 with the goal of improving medication safety. The founders came from a background in radiation oncology where they had seen tremendous developments in the accurate delivery of radiation therapy. They did not see the same level of quality control in the field of medical oncology so they set out to develop easy-to-use tools that could verify the accuracy of chemotherapy compounding to ensure that patients received the right drug at the right concentration.

“Right now we have three products. It started first of all with DrugLog, which is basically a device where you can take a small sample of the medication that you have prepared and the device will confirm that the medication is made of the right drug in the right concentration – and it only takes a few seconds to give you that certainty”, explains Mr Högberg.

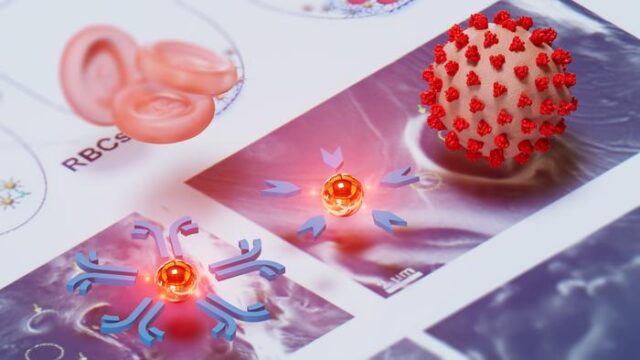

DrugLog uses light absorption spectroscopy to provide very quick verification of a prepared injctable drug. During the preparation of the dose, a small sample – 0.3-0.5 ml of the solution is withdrawn. It is put into a cuvette that is placed in the device and in two-five seconds the device will confirm that the prepared medication is correct. It will also show if the correct drug is present but in the wrong concentration. “It’s very quick [and] very robust. We have done several scientific studies on this to ensure that it’s accurate and provides reliable measurements”, says Mr Högberg.

There is no other easy-to-use system or device for checking the accuracy of the final product when patient-specific injections are prepared. When injectable drugs are prepared in hospital pharmacies there are quality assurance measures for in-process checks. What DrugLog provides is a quick and easy way to ensure that the end product is correct, explains Mr Högberg.

There are three main areas where DrugLog is in use today – manual injection preparation, robotic injection preparation and batch preparation. “When [we] talk about compounding we differentiate between ‘toxic’ and ‘non-toxic’. ‘Toxic’ is typically performed at the hospital pharmacy where you have specific rules and you have the process. ‘Non-toxic’ is prepared at the ward and we can help both those processes”, says Mr Högberg. The second area of application is in robot verification – “We have customers who have acquired a DrugLog device and are using it to confirm that their compounding robot is behaving consistently. So, every morning when they start up the robot they check that actually it knows that 10 ml is still 10 ml and so on by having the robot prepare paracetamol or something else and then they verify the concentration with DrugLog”, he says. The third area is batch production. When, for example, a hospital pharmacy produces batches of insulin infusion bags, DrugLog can be used for quality control. It is being used today in several places in Europe for this particular type of verification, notes Mr Högberg.

Toxic drugs are typically anti-cancer (chemotherapy) agents. “Most of our customers in Europe are using our products to verify chemo compounding and the good thing is you can do it in the same process as you prepare so ….. you can check the bag before you ship it off to the hospital ward. And the good thing is also that you do not open the bag after it has been sealed ….. so basically you take your sample while preparing the bag – meaning that once it has been sealed it won’t be opened until it comes to the patient” explains Mr Högberg. In addition to ensuring the integrity of the product this means that the risk of spillage and environmental contamination is minimised.

Visit the Pharmacolog website here.

Read and watch the full series on our website or on YouTube.